Precision, Efficiency, and Quality: Experience Ampersand’s Advanced Printing Solutions

At Ampersand, we are committed to investing in state-of-the-art technology that your business can leverage to bring your creative visions to life. Our advanced printing systems and software ensure very high-quality output, excellent colour fidelity, and exceptional efficiency.

We invest in the latest proven technology to stay ahead of the curve—and the competition. By continually researching and adopting the latest advancements in printing technology, we are constantly upgrading our service offering and are able to provide you with the latest and greatest.

High-Definition Staccato Printing

For your extra special printing projects, our High-Definition Staccato Printing is the gold standard in offset print production, providing unsurpassed “photo-like” quality, and an expanded colour gamut for a much, much better range of colour reproduction than traditional colour printing. Where traditional four colour process printing uses four inks, we use six. What does this mean to you? Brilliant colour. You have never seen greens, blues and oranges like this before. Ask us for a sample and a quote.

We understand that your success relies on high-quality, visually stunning print that enhances your brand—that’s why we’ve invested in cutting-edge equipment that guarantees outstanding results.

Kodak ColorFlow

We were the first in Canada to implement this level of colour management across the production floor. Our Kodak Colorflow Colour Management monitors and calibrates all output devices to the Gracol standard, ensuring colour accuracy and brand integrity regardless of application. The system works to ensure colour integrity from proof to final product, across all systems (offset printing, digital printing, and large format printing). Your brand colours are reproduced with perfect fidelity regardless of device—and over time.

Discover how our breakthrough printing solutions can transform your projects from ordinary to extraordinary. Whether you need large format printing, digital printing, or specialty finishes, our comprehensive range of services will deliver brilliantly.

Mitsubishi Colour Control System (MCCS-V)

We cannot stress enough how important correct colour is to us. Your colours are part of your overall brand; they were chosen with intent and must be reproduced exactly correct during the printing process. We understand that. Our Mitsubishi Colour Control System is designed to maintain colour accuracy and consistency on every page. It continuously compares the printed images to the original digital files, then makes automatic press adjustments to ensure colours are printing exactly as they should be. We ensure you never have to worry about colour fades or variations throughout a print run, or off-target colour.

The full equipment list

Our facility is home to some of the most advanced printing and finishing technologies in North America, including:

Prepress

- Mac & PC Platforms

- Kodak Prinergy Workflow

- Epson P9000 Commercial Edition Proofing System capable of 99% Pantone Matching

- Kodak Trendsetter 800 Quantum 2 CTP Device

- Fully integrated into Ampersand’s award winning JDF digital workflow

Digital Printing

NEW Xerox Iridesse Digital Printing

- Print up to 40” x 13” to make a big impact and include more content on a single page

- 6 Colour Press Digital Press – eye-popping, cost-effective embellishments on even the shortest runs with ability to print Metallic Gold & Silver as well as Spot Gloss Coating

- Extremely high quality, comparable to litho printing

- Consistent quality regardless of the length of your run

- Consistency between versions (for example large English jobs printed on a litho printing press compared to smaller French jobs printed digitally)

- Fast turnaround time without sacrificing quality

- Smaller runs of larger format jobs (up to 6 pages) without the added cost of litho

- Capable of printing on a wide range of substrates from lightweight paper to 18pt board, plastics & magnet

- More accurate spot colour matching to ensure brand integrity

Xerox 4112 Digital Printing Press

- Printable image area of 12.75” x 18.75”

- High speed monochrome printing

- Capable of printing on a wide range of substrates

- JDF compliant

Neopost AS950C Digital Envelope Printer

- Full colour envelope printing for short and medium runs

- Ability to print full colour variable graphics and text

- Ability to print full bleed envelopes up to 6x9"

Litho Printing

Mitsubishi Diamond 3000LX

- 28” x 40” 6 Colour + Aqueous Coater, with a printable image area of 27” x 39”

- Complete air transfer system ensures mark free printing and enables us to print on a wide range of substrates from onion skin to 40pt board and plastics at speeds up to 16,000 sheets per hour

- Fully automated and integrated to Ampersand’s award winning JDF digital workflow

- First in North America to be fully JDF integrated to both Prepress and MIS (Management Information System)

- Fully automated print control system monitors print quality and colour making adjustments automatically as required

Large Format Printing

Mutoh Value Jet 1624

- Handles 64” wide media, length as long as you wish

- Eco Solvent Ink

- High Substrate range (styrene, coroplast, 40pt card stock, magnetic, vinyl, fabric etc.)

Roland VersaCamm

- Handles 54” wide media, length as long as you wish

- Eco Solvent Ink, including white

- Kiss cut on the fly

- High Substrate range (styrene, coroplast, 40pt card stock, magnetic, vinyl, fabric etc.)

Roland VersaExpress

- Handles 64” wide media, length as long as you wish

- Eco Solvent Ink

- High Substrate range (styrene, coroplast, 40pt card stock, magnetic, vinyl, fabric etc.)

Summa Kiss Cutter 160

- Digital Dieline to kiss cut

- Handles 72” media, length as long as you wish

Bindery

54” Polar Cutting System

- Automated jogging & counting systems

- Fully automated and integrated into Ampersand’s award winning JDF digital workflow

Duplo DC-646 Automated Finishing System

- Automated cutting, perforating, and creasing

- Helps bring Print on Demand unit pricing closer to that of traditional pick and pack workflows

Morgana Digifold Pro

- Automated creasing & folding machine

- Die score and fold in one step eliminates cracking of digitally printed materials while decreasing turnaround

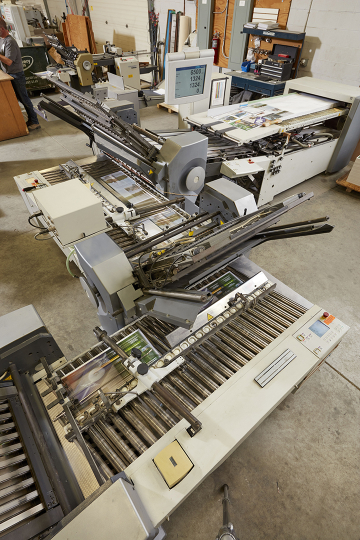

Stahl TH82 Folder

- Fully automated minimizing operator intervention during make ready, increasing accuracy and efficiency while reducing waste

- Equipped with channel scoring device enabling die quality scores inline

- Fully automated double gate fold attachment increases accuracy and allows for a gap of as little as 1/16” (.0625”)

- Integrated with our vision system for processing of personalized pieces

Stahl B20 Folder

- Equipped with channel scoring device enabling die quality scores inline

Heidelberg ST100 Saddle Stitching Line

- Cover feeder equipped with channel scoring device enabling inline die quality scoring and folding of cover, eliminating the time and cost of folding

- Features automated quality control sensors

- Equipped with both regular stitch and loop stitch heads

- Integrated with our Vision System for processing personalized booklets

Morgana Auto Creaser Pro 50

- 35” sheet

- Infinite Scoring

- Perforations

- Die scoring capabilities

Royal Sovereign Laminator

- Hot & Cold Laminates

- Wide format

Hot Glue Padding Machine

- We can make “take one” pads for your next marketing campaign

Wiro & Plasticoil Binding, Drilling, Shrink-wrapping, Kitting, and Distribution

Mailing

Kirk Rudy Net Jet Addressing System

- High-speed, high-quality, addressing on a wide variety of materials and substrates

- Able to run as a standalone machine or inline with our folders and saddle stitching line, reducing costs and turnaround times

- Ability to inkjet on aqueous coated surfaces eliminating the need for knock outs

Kirk Rudy Match Mate Vision System

- 4 Camera matching system capable of reading text & barcodes

- Can match multiple pieces to each other or to the supplied database

- Writes a time stamp back to your database with the exact time the piece was matched and inserted

- Guarantees set integrity (matching of multiple personalized pieces)

- Integrated into machines throughout our facility

Netpak 6 Station Inserter

- Up to 11,000 pieces per hour

- High-speed insertion of up to 6 pieces

- Double, missed insert & missed envelope detection for mail integrity

- Integrated with our vision system to ensure set integrity (can match up to 4 inserts and print matching address on outer envelope)

Bell & Howell 6 Station Envelope Inserter

- Up to 6,000 pieces per hour

- High-speed insertion of up to 6 pieces

- Double and missed insert detection for mail integrity

Minipack Mail Bag Semi-Automatic Poly Bagger

- High-speed insertion and sealing of mail pieces into polybags

Rigid Box Manufacturing

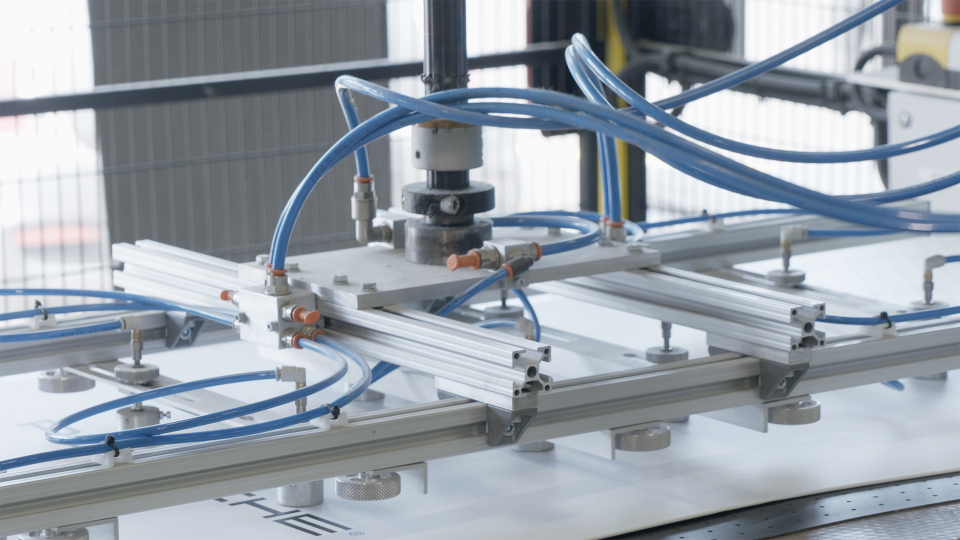

Peroni Ruggero PWS

- Automated case wrapping/lining machine

- Laminate 1 to 5 pieces of board to a litho printed label and turn in all 4 edges for making game boards, hard covers, puzzle boards, and book box covers

- Also used to laminate litho labels to corrugate for short run corrugated packaging

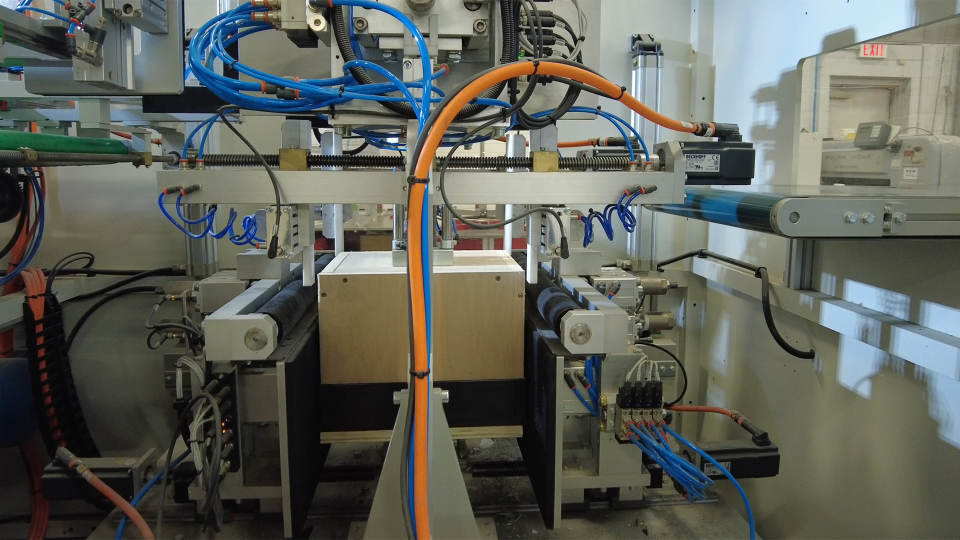

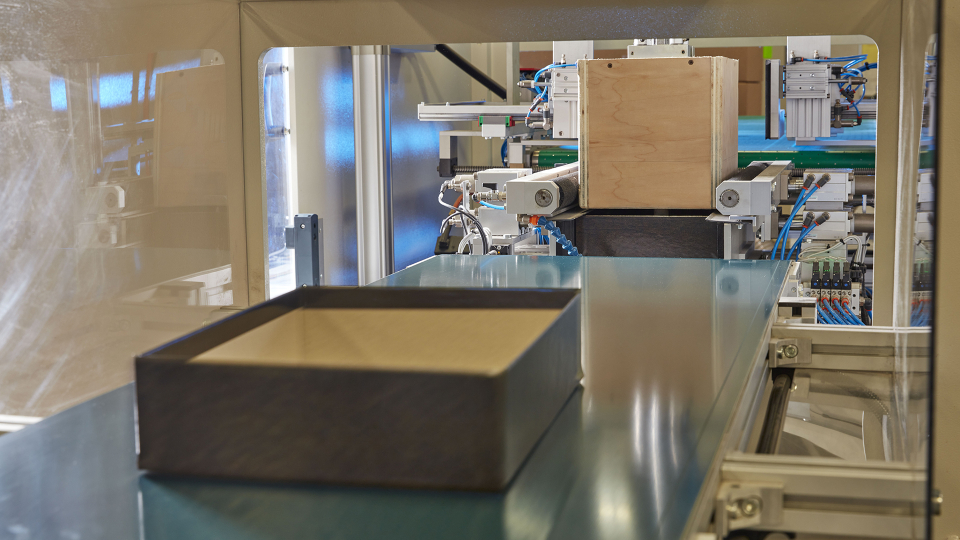

Peroni Ruggero Boxwrap 24

- For wrapping of setup boxes

- Fully automated setup

- Tooling manufactured inhouse, reducing cost for short runs

- Able to produce boxes up to 9.5” high, ideal for 2-piece bottle sleeves

Zund G3 XXXL 10’ x 10’ CNC Cutting Table

- Digital die-cutting, creasing, and routing

- Wide array of capabilities:

- Kiss cut vinyl stickers

- Die-cut and crease short run packaging

- Contour cutting signage and displays (foam core, coroplast, corrugate)

- Custom cutting foam

- Engrave or route wood, acrylic, aluminum etc.